Why Bright Bars is Important? Why one should use Bright Bars?

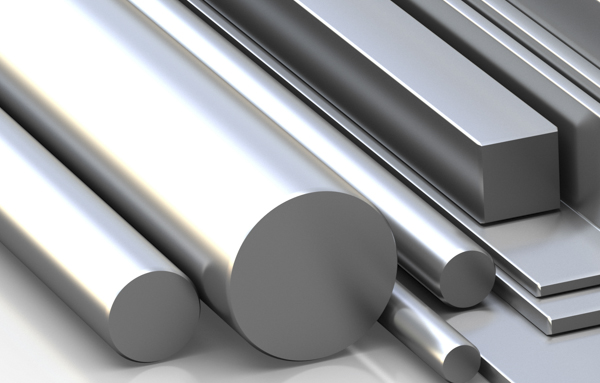

Bright Bars are plain bars fabricated from hot circled plain bars or wire rods by one of more cold finishing procedures. Featured with smooth and bright surface, bright bars have great and accurate tolerance on the dimensions. These bars are loaded with enhanced mechanical attributes, dimensional precision, and exterior veracity. Another factor that makes it a popular choice in the market is its higher machinability. All these qualities lead to a good number of advantages for the end users, especially over hot rolled bars or black bars.

Amazing Mechanical attributes

As mentioned above, bright bars are produced by cold finishing, which increases its resistance, yield and tensile potency. These features make the bars light in weight by reducing the design mass. The bright bars eliminate expensive heat treating that reduces the expenditure from the user’s end. Unlike other kinds of bars, it allows the utilization of the less expensive score. Using this product allows the users to enjoy long lasting service performance along with amplified fatigue strength. In addition, it offers better wear and corrosion confrontation quality that leads to lasting durability. What’s more? Bright bars offer enhanced resist handling damage and quicker annealing reaction along with cross sectional consistency.

Dimensional Meticulousness

In comparison to other kinds of bars, bright bars offer precise and steady dimensions or geometries. It is a great feature that helps in reducing the machining process. This property eliminates the whip that results in shuddering while machining. There are quite minimum possibilities of marks on collets, hawker and fingerprints throughout the process. Machine loading is easy and there is no need to make various adjustments in the machine for size changeability. Additionally, the use of bright bars improves work-holding compatibility and facilitates you to get net shape while eliminating fragment and yield loss during the production unit.

Surface Reliability

Bright Bars are appreciated by experts for ultimate surface reliability. As it is produced by cold drawing and polishing procedures that offer better surface texture that brings various advantages. Smooth texture remarkably decreases machining process and simplify manual handling and machine loading. The texture significantly improves eddy current testing warmth and consistency.

Better Machining Performance

Bright bars are designed and used to improve machining performance significantly. Better beam strength, ductility, smooth texture and enhanced dimensional precision, etc. lead to better performance. Bright bars allow the use accurate colleting and increase work holding protection with larger bearing contact regions. Using bright bars allow you to recover part size control through less lateral deflection. It increases tool life and reduces abrasion with oxide-free and smooth bar surfaces. Bright bars are recommended by experts as these products reduce wear on machine parts and collets and less lubricant infectivity because of deficiency of hot mill texture scale. In addition, it reduces maintenance cost of machines.

Bright bars are frequently suggested and recommended by the experts over Hot Rolled Bars or Black Bars and other bars. The above mentioned explanation may help you to understand why bright bars are important and beneficial.