4 Elements Customers Want in a Bright Bars

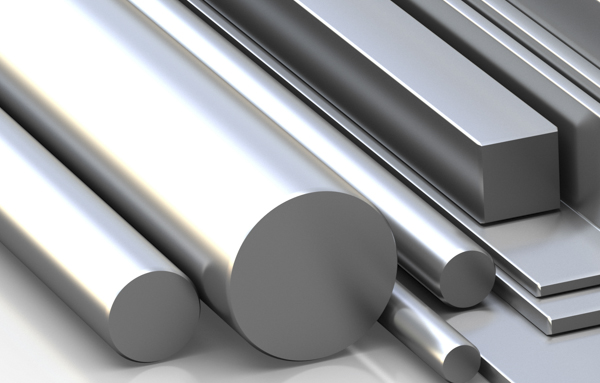

Bright bars are steel bars manufactured with precise shapes, sizes and measurements and they are smooth and shiny surfaced with a bright finish. Bright bars have high tensile strength and bendable properties which make them versatile to use in various types of industries. You can get square, hexagonal, flat or round bars in many sizes depending on its application. There is a differentiation in the grades of the bars according to their application. Due to qualities like high tensile strength and corrosion proof bright bars are used in manufacturing auto parts for vehicles by forcing them into particular shapes. Bright bars are abrasion proof and rust proof making them apt for use in the automobile industry. Here are four elements required in bright bars by clients:

• Mechanical properties of bright bars:

This is a major element customers require in the bars as with enhanced mechanical properties and larger dimensional precision, these bars can provide the advantages of accurate designing. When the bar is cold drawn, the hardness, tensile strength, and yield are elevated, leading to the reduction of overall weight, diminishes expensive heat treatment, allows usage of inexpensive grade, cross sectional uniformity is elevated, annealing response is quicker. Handling damage is reduced and wear and corrosion resistance are enhanced. Clients require high-quality bars with elevated mechanical properties to make better use of these bars in other products.

• Dimensional accuracy:

Bright bars which are cold drawn, polished, ground or turned provides highly accurate and reliable cross section uniformity, straightening and bar end provisions which can reduce or diminish machining, decrease vibration or whip while machining, decrease stress on fingers, pusher or collets during machining, relieve, machine loading, reduction of adjustments in machines due to size variability, improvement in work holding and fixture compatibility and decrease in scrap and production loss while manufacturing. The clients require dimensional accuracy in automobile or other products manufactured from bright bars.

• Surface Integrity:

The surface of the bright bars is smooth due to cold drawing, grinding and polishing due to which it provides advantages like: reduction or elimination of machining, simple handling and machine loading, great improvement in eddy current testing sensitivity and great reliability. The bright bars are also turned and grinded due to which the surface is free of several abnormalities which can eradicate decarburization, give a flawless surface and decrease requirement of overall machining. As the bright bars are smooth and plain with polished surface, they bear qualities to be used in several industries and due to surface integration they reduce other requirements of smoothening during auto parts manufacturing process.

• Machinability:

As bright bars have properties like elevated beam strength, low ductility, enhanced dimensional accuracy and tidy surface, they affect the machining performance in a positive manner by helping in a usage of quick, precise and activated collecting. Work holding security is enhanced with greater impact on a surface area. There is a considerable improvement in the machined surface finish due to decreased tool welding’s on ductile grades and there is also advancement in part size control due to small lateral deflection. There is a great reduction in wear and tear of machine parts and collets along with depleted lubricant stains as there is no hot mill surface scale.

Bright bars help the designing engineers to lessen the time and costs of manufacturing and enhance the performance of the products. They are desired by all the manufacturers in various industries due to accuracy in the elements.